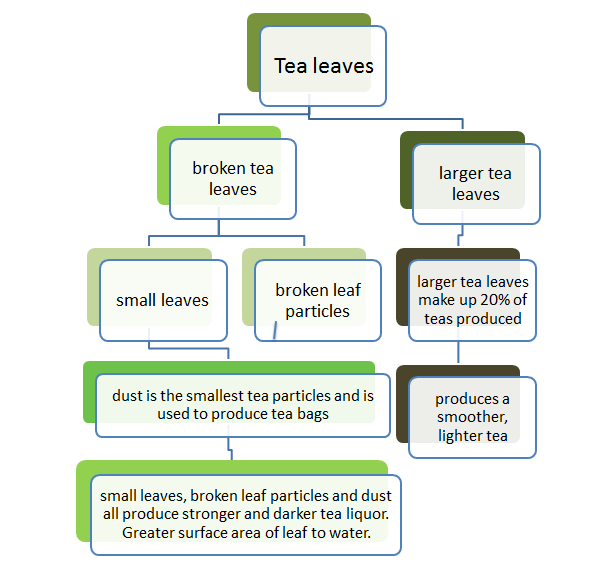

The tea grading system used in tea grades is very inconsistent and not used in every country the produces tea. The criteria for grading tea is by the dry leaf, not taste or anything intuitive like that. Tea is divided into two categories, broken leaf grades and leaf grades. For example, when there is a “B” associated with a tea it is referring to the tea leaves and in this case means that smaller pieces of leaves are used. This means that there is a greater surface area of leaf to water implying a stronger brewed tea.

The British influenced countries use a lettered grading system. These countries include India, Sri Lanka and African tea producing countries. The Chinese name their teas while the Japanese describe the tea leaves and Taiwan use a numbered system and isn’t normally used.

Leaf grading

- Done in British influenced tea producing countries such as India, Sri Lanka and Kenya.

- It describes the physical characteristics of the leaves.

- Does not describe the flavours of the liquor.

The tea grading system is different in different parts of the world. There is no consistency or standard grading system.

Tea grades in India, Sri Lanka and other British influenced countries:

Fannings/fine. This is the finest siftings of the dried tea leaves. It is useful when making tea blends for tea bags.

There are many broken tea grades.

Broken tea grades

FP = Flowery Pekoe. The leaves are rolled in balls.

P = Pekoe. These are short, coarser leaves.

OP= Orange Pekoe. The leaves are long and pointed and larger than FOP, flowery orange Pekoe. These leaves are harvested when the end of buds open up into leaves.

FOP= flowery orange Pekoe. This tea is made from the end of a bud and first leaf of each shoot. It contains fine, tender young leaves rolled with correct proportion of the tip. It is made from the delicate end pieces of the buds which guarantees quality.

GFOP=Golden flowery orange Pekoe. This is FOP with golden tips, the very end of golden yellow bush.

TGFOP=Tippy golden flowery orange Pekoe. FOP with a large proportion of golden tips.

FTGFOP=Finest tippy golden flowery orange Pekoe. Exceptionally high quality FOP.

SFTGFOP=Special finest tippy golden flowery orange Pekoe. Very best of FOP.

Tea grading in other parts of the world that are tea producing leaders.

China

Here the tea grading system differentiates by the leaf’s appearance. There is no indication of the quality of the tea liquor. The grades includes:

- Mao feng

- Pearls

- Pi Lo Chun

- Drangonwell

- Gunpowder

- Chun mee

Japan

The grading system in Japan uses the leaf’s appearance. The categories include:

- Choice

- Good

- Medium

- Common

- Numbs

- Fannings

- Dust

This system is not usually used though. Instead, teas are divided by leaf type.

- Sencha

- Gyokuro

- Matcha

Taiwan

In Taiwan a numbered system is used, 1st, 2nd, 3rd, etc.

Challenges of the tea grading system

There a number of challenges with the tea grading system. From above it can be seen that there is no standardized or universal system. The grading is left to the tea garden. There is no regulatory body that conducts the grading. This can lead to a very subjective grading of the tea. The grading of tea only provides information about the physical characteristics of the dry leaves not the flavours of the liquor and the flavour of the liquor is the main part. With all this inconsistency with tea grading a Ceylon TGFOP tea will taste quite different from an Assam TGFOP. However there are some benefits of grading teas.

Benefits of tea grading:

It is beneficial for tea blenders who make original blends. A small leaf grade increase the surface area of the leaf to water which implies a stronger liquor which implies a blender can create a flavour character that they want.

Tea Taster

The tea taster is a special person who helps verbalize the flavour of the tea.

Role of tea taster

- Specialised role

- Requires years of training and experience

- Requires knowledge of all facets of the industry. For example,

- Types of tea

- Production methods

- Flavour characteristics

- Cultivation

- Manufacturing process

- During the peak tea producing season, tea tasters can taste 200-300 teas per day.

- Tasters look for,

- Flavours of the liquor

- Defects in the leaf

- How the leaf has been manufactured.

Tea production process

While tea comes from a plant, it is harvested. As with any other harvested crop, there are many factors that influence the final product and in this case, the flavour of the tea. Some of the influences of the flavour of the tea include, the altitude, climate, soil, harvest time and processing of the tea. Depending on these secondary factors the flavour profile of the tea can be strong, nutty, mild, malty flowery and so many other profiles. The tea production process is what differentiates the different teas. For example, when tea leaves are harvested from the camellia sinensis plant in some cases, let’s say for black tea,

- After about 2-3 weeks of growth, 2 leaves and 1 bud are plucked off the Camellia sinensis plant.

- After about 2-18 hours of withering, laying around in the sun and air, about 45%-65% of the moisture has been lost from the leaves.

- In the orthodox method of tea production:

- There is controlled rolling of the leaves.

- Oxidation of the leaves takes place for 2-3 hours resulting in a coppery colour of the leaves.

- The leaves are then passed through a dryer for 20 minutes. This stops the oxidation process.

- The dried leaves are put

through a sieve which determines the grade of the tea.

- Leaf

- Broken

- Fannings

- Dust

- All of which depends on what goes through the sieve.

- Then the tea is packaged by grade.

For green tea there are two different methods of stopping the oxidation process that occur. In japan the leaves are steams immediately after picking to prevent any oxidation to occur. In China the fresh leaves are fired in a hot pan, again to minimize any oxidation to occur after picking.

CTC – Cut Tear, Curl

CTC, cut, tear, curl method of production is an automated process. This process expedites the tea production process resulting in more uniform leaves which is ideal for tea bags.

- The leaves are freshly harvests, 2 leaves and a bud.

- They are placed in a large withering trough where the moisture evaporates from the leaves.

- After about 18 hours in these withering troughs the leaves become limp and easy to work with.

- At this point the leaves are cut and smashed until the leaves reach a uniform size.

- The leaves are placed on a conveyer belt and move over a fan of cool air where oxidation occurs.

- This ensures that the leaves do not overheat and the flavour is maintains.

- The leaves are then dried for 15 minutes in 270F heat.

- Tea leaves are divided into

3 grades

- BOP – Broken orange pekoe

- PF – flowery pekoe

- Dust – dust

Reference

- Tea 101, Academy of Tea, URL: https://academyoftea.org/tea101/

- Ronnefeldt Tea Production, YouTube, URL: https://youtu.be/H7XMocbSw8Q

- 3 – Cut Tear Curl (CTC) Tea Manufacture.mp4, YouTube, URL: https://youtu.be/5653TXCjaw4

- My first time making scones - March 26, 2024

- Disappointing Visits to the Ripon and Plateau Farmers Markets - September 30, 2023

- The Ultimate Guide to Frozen Raw Dog Food: Benefits, Selection, and Transition Tips - September 25, 2023